grp pipes and fittings for ship building

...

...

...

...

...

...

...

...

...

...

- Applications of the 6302 Bearing

- * Renewable energy Wind turbines, hydroelectric generators, and other renewable energy systems that require reliable and efficient bearings.

- 2. Automotive The 48548 bearing is used in automotive components such as transmissions, differentials, and wheel bearings.

- The 51312 thrust bearing is a precision-made component that consists of a series of balls or rollers arranged in a raceway. These components work together to provide a low-friction surface for the load to be supported and distributed evenly across the bearing surfaces. This design helps to reduce wear and tear on the bearing, prolonging its lifespan and ensuring optimal performance.

- * Limiting speed 13000rpm

- Despite their ruggedness, it is important to ensure that cylindrical roller bearings are installed correctly and that the surrounding system is properly aligned. Misalignment can cause accelerated wear, reducing the overall efficiency and life expectancy of the bearings. Proper installation and regular inspections are therefore critical to harnessing the full potential of these mechanical wonders.

- Maintenance and Care

- The advanced materials used in the construction of these bearings, often high-grade steel or specialized alloys, ensure durability and resistance against wear and tear

- 2. Reduced Downtime The ease of maintenance and long service life of the 638 ZZ bearing minimize downtime and increase productivity. Businesses can avoid costly repairs and replacements, resulting in higher profitability.

- Cylindrical thrust bearings are essential components in many mechanical systems, providing support for rotating shafts and helping to minimize friction. These bearings are designed to handle axial loads and ensure smooth operation of machinery.

- In addition to these dimensions, the 6403 bearing also has a specific radial and axial load rating. Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis

Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis

Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis 6403 bearing dimensions. These ratings, along with the bearing's speed capabilities, are essential factors to consider when selecting the appropriate bearing for a specific application.

6403 bearing dimensions. These ratings, along with the bearing's speed capabilities, are essential factors to consider when selecting the appropriate bearing for a specific application. - In conclusion, the NJ206 bearing stands as a testament to the ingenuity of modern engineering. Its design, functionality, and versatility make it a go-to solution for engineers worldwide. As technology continues to evolve, so will the NJ206, adapting to new demands and pushing the boundaries of what bearings can achieve. Whether it's in the heart of a bustling factory or the intricate workings of a high-performance engine, the NJ206 bearing remains a symbol of precision, strength, and unwavering dependability.

- Moreover, the 6312 zz bearing offers a competitive edge in terms of installation and replacement ease. Its design allows for simple insertion into housings and removal when necessary, minimizing downtime and potential damage during maintenance procedures.

- Proper maintenance is essential for ensuring the longevity and optimal performance of Bearing 51309

- Bearing manufacturing machines are designed to handle the complex task of creating precision bearings. These components are essential in a wide range of applications, from automotive engines to wind turbines, and their performance can significantly impact the overall efficiency of these systems. Traditional bearing manufacturing methods were often labor-intensive and time-consuming, but modern machines have streamlined the process, reducing production times and increasing output.

- The inner diameter of a bearing is perhaps the most critical dimension. It must be precise to accommodate the shaft or spindle on which the bearing will be mounted. If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing

If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing

If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing 6313 bearing dimensions. Similarly, the outer diameter and width must also be accurate to ensure proper fitting within the housing or assembly.

6313 bearing dimensions. Similarly, the outer diameter and width must also be accurate to ensure proper fitting within the housing or assembly. - 5. Replace the bearing at the first sign of failure. Delaying replacement can lead to further damage and reduce the overall lifespan of the mechanical system.

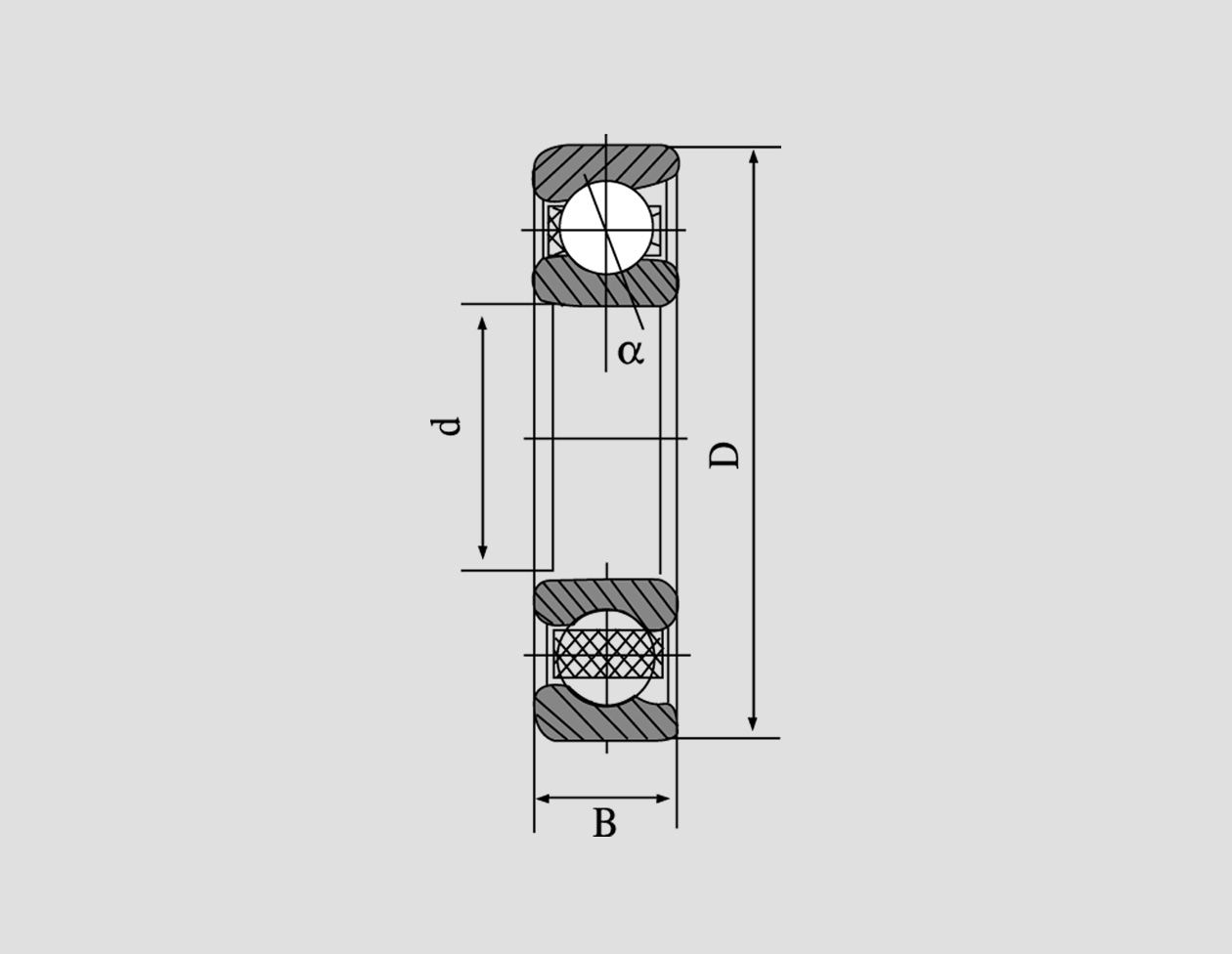

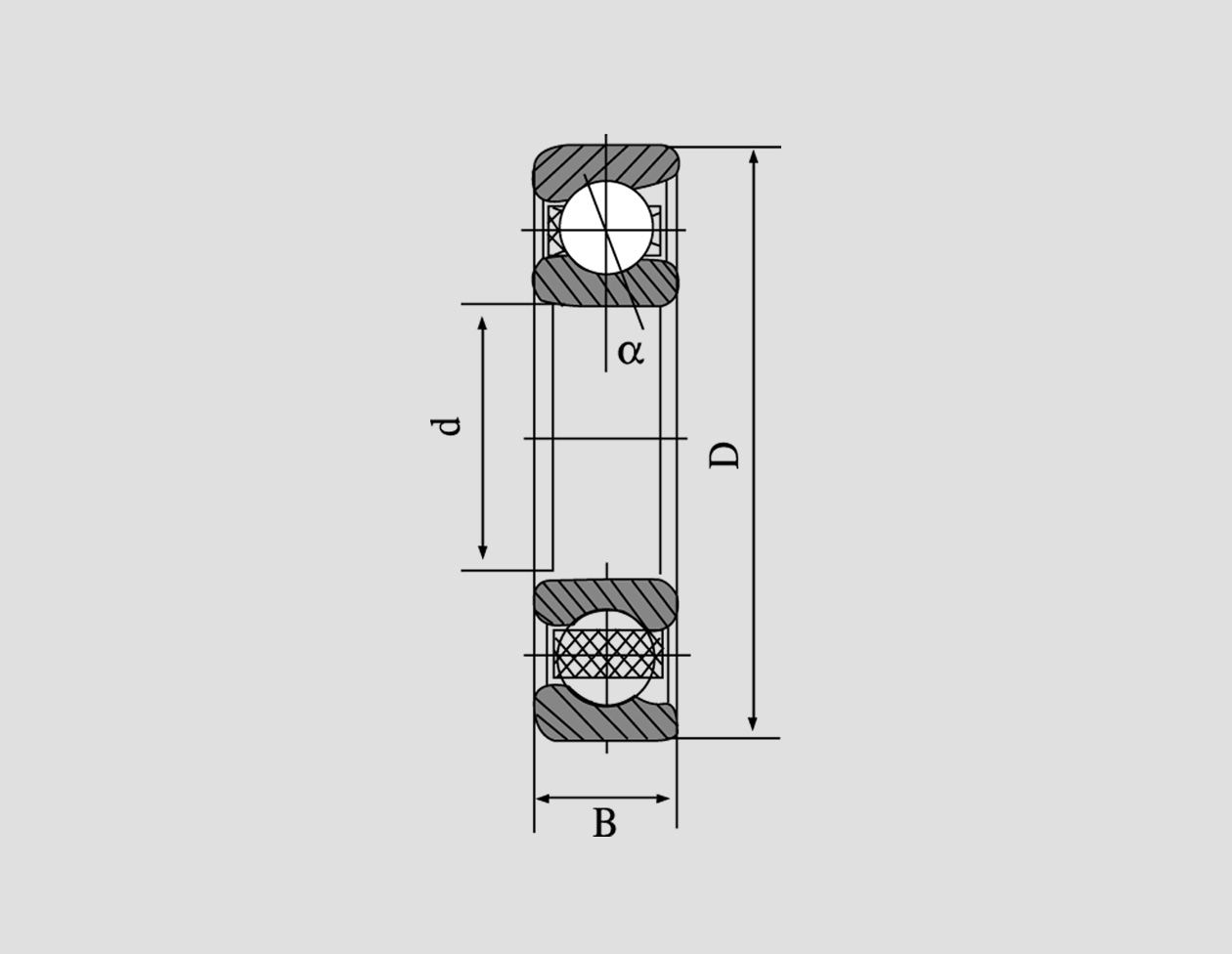

- One of the key features of angular contact ball bearings is the contact angle. This angle is the angle formed between the axis of the bearing and the line of contact between the balls and the raceways. By adjusting the contact angle, the bearing's ability to support axial loads can be optimized.

- Tapered bearings are a unique type of bearing that has found widespread use in various industries due to their ability to manage high-speed and heavy-duty operations. These bearings, also known as tapered roller bearings, have an inner and outer ring with a tapered raceway between them. The rollers are tapered so that the smaller end of the roller lines up with the smaller end of the cone. This design allows for the even distribution of loads along the length of the roller, reducing friction and wear.

- In addition to their load-handling capabilities, taper roller bearings are also known for their high-speed performance. The tapered design of the rollers reduces friction and heat generation, allowing the bearing to operate at high speeds without compromising performance. This makes taper roller bearings ideal for applications where speed is a critical factor.

- NSK, on the other hand, focuses on innovation and sustainability

spherical bearing manufacturers. They have developed eco-friendly bearings with reduced friction and increased energy efficiency. Their spherical plain bearings, made from corrosion-resistant materials, offer excellent performance in wet or corrosive conditions.

spherical bearing manufacturers. They have developed eco-friendly bearings with reduced friction and increased energy efficiency. Their spherical plain bearings, made from corrosion-resistant materials, offer excellent performance in wet or corrosive conditions. - The 6210 2RS bearing, a precision-engineered component widely used in various industrial applications, has undergone significant changes over the years. These changes have not only improved its performance but also expanded its applications, making it an integral part of modern machinery.

- In conclusion, the 628zz bearing represents a pinnacle of miniature bearing technology. Its combination of sealed protection, lightweight design, and durability has made it a favorite among engineers seeking reliable rotational solutions. As technology continues to advance and the demand for smaller, faster, more efficient machines grows, the 628zz bearing is poised to remain a critical component in the evolution of rotational systems.

- The versatility of the 6311 bearing makes it suitable for a wide range of applications. It is commonly used in conveyor systems, pumps, fans, and other rotating machinery. In the automotive industry, it can be found in engine components, transmission systems, and suspension systems. Aerospace applications include landing gear systems, propeller shafts, and aircraft engines.

- 6202 2rs c3 bearings are designed to operate at high speeds while maintaining low friction and minimal noise levels. They are also capable of handling both radial and axial loads, making them suitable for a wide range of applications. The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance

The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance

The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance 6202 2rs c3 bearing.

6202 2rs c3 bearing. - Double row deep groove ball bearings are a reliable and versatile solution for a wide range of applications. By understanding their design, specifications, applications, and maintenance requirements, users can select the appropriate bearing for their specific needs and ensure optimal performance and longevity.

- The inner diameter of the 6321 bearing is the distance between the two inner rings. For the 6321 bearing, the inner diameter is typically 105 mm. This dimension determines the size of the shaft that can be mounted within the bearing, as well as the amount of radial space available inside the bearing.

- Regular maintenance is essential to ensure the long-term performance of bearing ID 80 OD 140 taper roller bearings

bearing id 80 od 140 taper roller. Follow these maintenance guidelines

bearing id 80 od 140 taper roller. Follow these maintenance guidelines - Smooth Rotation: The deep groove in a ball bearing allows for smooth and controlled rotation of shafts and other components. By providing a continuous and circular track for the rolling elements, the deep groove design ensures that the bearing can operate with minimal vibration and noise, contributing to the overall smoothness of the mechanical system.

- The Unparalleled Performance of 6004 Ball Bearings

- Material Composition

- Despite their robust nature, double row thrust ball bearings require proper installation and maintenance to ensure optimal performance. Regular lubrication is crucial to prevent excessive friction and wear, while correct alignment is essential to avoid premature failure. Moreover, regular inspections should be conducted to detect any signs of damage or fatigue, such as deformation, cracks, or excessive noise.

- Introduction

- Bearing, NJ, is known for its annual cultural events that bring the community together

- Choosing Between Cylindrical Roller Bearings and Ball Bearings

- The dimensions of a bearing refer to its physical measurements, including its diameter, width, and thickness. These measurements are not arbitrary but are carefully calculated to ensure that the bearing can perform its intended function effectively. For example, the diameter of a bearing is directly related to the amount of load it can support. A larger diameter means that the bearing can handle more weight, making it suitable for heavy-duty applications. On the other hand, a smaller diameter bearing is better suited for lightweight applications where space is limited.

- One of the key advantages of using a deep groove bearing puller is its ability to handle a wide range of bearing sizes and types. Whether you need to remove a small bearing or a large one, a quality puller will be able to get the job done efficiently. Additionally, these tools are relatively easy to use, even for those without extensive mechanical experience.

- The 6005 2RS C3 bearing is a widely used component in machinery and equipment across various industries. This type of bearing is designed to withstand high radial and axial loads while providing smooth and reliable rotation for the shaft it supports.

- 3. Replace the bearing if it shows signs of severe wear or damage.

- One of the key benefits of the 6301 ball bearing is its high efficiency and durability. The design of the deep groove ball bearing allows for smooth and quiet operation, even under heavy loads and at high speeds. This means that equipment using the 6301 ball bearing can operate efficiently and reliably without excessive noise or vibration

6301 ball bearing.

- 6. Limiting Speed 13,000 rpm

- * Replacing the bearing if it shows signs of severe wear or damage

- When comparing durability, cylindrical roller bearings generally have a higher capacity for load carrying due to the larger contact patch between the roller and races

cylindrical roller bearing vs ball bearing. However, they may not perform well under impact loads or high-speed applications because of their design. Ball bearings, while capable of handling combined loads, may not withstand extremely heavy radial loads as effectively as their cylindrical counterparts.

cylindrical roller bearing vs ball bearing. However, they may not perform well under impact loads or high-speed applications because of their design. Ball bearings, while capable of handling combined loads, may not withstand extremely heavy radial loads as effectively as their cylindrical counterparts.

Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis

Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis Radial load refers to the force acting perpendicular to the bearing's axis, while axial load pertains to the force along the same axis If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing

If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing If the inner diameter is too large or too small, it can lead to excessive wear and tear or even failure of the bearing

The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance

The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance The rubber seals on the bearing help prevent contamination and moisture from entering the bearing, which can extend its lifespan and performance